CHARLOTTE, N.C. — (BUSINESS WIRE) — January 16, 2024 — IperionX Limited (IperionX) (NASDAQ: IPX, ASX: IPX) is pleased to release a letter to shareholders from the Company’s Chief Executive Officer Anastasios Arima.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20240116767247/en/

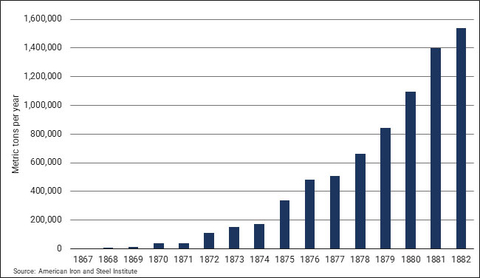

Figure 1: Bessemer steel production in the U.S. 1867-1882 (Graphic: Business Wire)

Dear IperionX Shareholders & Stakeholders,

As we embark on a new year and reflect on the remarkable accomplishments made over the past 12 months, I am pleased to confirm that the IperionX team have already turned their focus and dedication to delivering another year of significant growth, innovation and success. Before I begin, I would like to provide some historical context for why this year is expected to be a critical inflection point for our company and why we have so much conviction in the exceptional potential for IperionX.

For nearly 3,000 years, steel was a niche product, primarily because it was significantly more expensive than iron. In 1853, the inventor Henry Bessemer began research in alternate steelmaking methods, which ultimately led him to discover a new low-cost process for producing steel in 1856. It took two more years of testing and development for Bessemer to be in a position to commercialize his new process, by opening the Bessemer Steel Works in Sheffield, U.K. in 1858. The first commercial Bessemer steel plant in the U.S. was built in 1864 and between 1867 and 1882, U.S. production of Bessemer steel grew 53% annually. Over the same period, the breakthrough Bessemer steel technology led to a cost reduction of over 70% and ushered in a new age in steel production that continued for over 150 years. Commercialization of the technology was the critical inflection point. The new production technology radically lowered the cost of steel production, allowing Bessemer to scale quickly, profitably capturing market share and making the Bessemer Process a driving force of the Industrial Revolution.

Our core titanium refining and processing technologies, Hydrogen Assisted Metallothermic Reduction (HAMR) & Hydrogen Sintering & Phase Transformation (HSPT), were first patented by Dr. Z Zak Fang in 2016 and 2011 respectively. IperionX now aims to successfully reach its own “Bessemer Moment” as we commission our first commercial titanium production facility, using the HAMR process, in Virginia in 2024. Our noteworthy accomplishments in 2023 have set a solid foundation for a successful commercialization in 2024 and we expect this milestone to be a critical inflection point for the future of IperionX.

A summary of our most significant achievements in 2023:

Building our Titanium Metal Commercial Facility in Virginia

We executed and expanded on our initial plans, announced in September 2022 by Virginia Governor Glenn Youngkin, to build the world’s largest recycled titanium metal powder facility in South Boston, Virginia. In April 2023, we detailed our plans to build 1,000+ metric tonnes per annum of titanium metal production capacity in a 50,000 sq. ft. building within the Southern Virginia Technology Park (SVTP), located at 1080 Confroy Dr. (the “1080 Building”), which is now expected to reach full capacity by 2026. In November 2023, we bolstered our presence at the SVTP with a second 15,000 sq. ft. building located at 1092 Confroy Drive (the “1092 Building”), which is expected to be commissioned in the second quarter of 2024, and will utilize the titanium powder produced in the 1080 Building to:

(1) use our forging technologies (HSPT) to produce traditional titanium mill products (plate, bar, wire, etc.) and near net shape titanium products; and

(2) apply additive manufacturing to produce complex 3D printed titanium products.

Together, our 1080 & 1092 Buildings are expected to create an innovative titanium metal manufacturing campus, demonstrate the commercial scalability of our HAMR and HSPT technologies, and showcase how we plan to revolutionize the titanium value chain in a manner reminiscent of Bessemer’s historic achievement.

Breakthrough Large Scale Commercial Test Runs of the HAMR Process

The HAMR process represents a revolutionary shift in titanium refinement and production. While the science is complex, we view its application as relatively straightforward as it uses conventional, off-the-shelf, low-cost furnace technology that we have already de-risked through comprehensive testwork in 2023. At our leading European furnace supplier, the IperionX team completed two successful furnace hot test runs which scaled the batch size by a factor of 10x, from ~40kg to over 400kg, while reducing cycle time by over 70%, surpassing the core assumptions that underpinned our engineering studies for the Virginia production facility. In light of these successful results, we are now advancing detailed engineering studies for our planned expansion in Virginia, which we believe has significant potential to deliver higher titanium productivity at materially lower costs.

Advancing our Industrial Pilot Facility (IPF) in Utah

IperionX assumed ownership of the IPF in early 2022, and since then we have materially upgraded the facilities to increase the nameplate capacity and enhance the performance of the operation to produce high quality titanium metal powder for customer engagement. Simultaneously, our team worked on the design and engineering of the Virginia commercial titanium facility, which enabled us to secure permits for the Virginia facility in October 2023 and begin construction in December 2023.

Customer Engagement with Global Leaders

We engaged with a wide range of potential customers including Ford, Lockheed Martin, Canyon, and GKN Aerospace. Our 3D printing capabilities yielded our first commercially available titanium product, an innovative Panerai x Brabus titanium timepiece. In addition, we engaged with Lockheed Martin, GKN Aerospace and the U.S. Army to replace traditional titanium mill products, in this case titanium plate, providing a new domestic and sustainable source to enhance their critical supply chains. Simultaneously, we secured new sources of titanium scrap feedstock, signing agreements with ELG Utica (part of the Aperam Group) and Heroux Devtek (a leading aerospace supplier).

Winning Government Contracts & Industry Awards

2023 began with IperionX winning the U.S. Air Force Research Laboratories Grand Challenge in recycling titanium scrap and powder. Our titanium technologies were then recognized by winning an R&D 100 Award, which is the pre-eminent science and technology award competition that recognizes new commercial products, technologies and materials for their technological significance. Important milestones also included UL validation of the 100% circularity of our titanium production process and the completion of the first peer reviewed and ISO compliant ‘life cycle assessment’ which highlighted our industry leading low-carbon footprint.

Securing Permits for our Titan Critical Minerals Project in Tennessee

We successfully secured all key permits for our 100% owned Titan Project, which is one of the largest titanium, zircon and rare-earth mineral resource in the United States. Permitting was completed in under 10 months – a testament to our sustainable approach to minerals extraction and our team’s commitment to the communities where we operate. Discussions are ongoing with potential corporate partners regarding opportunities to accelerate Titan Project feasibility studies and development. While the Titan Project is integral to our long-term ambitions to build a fully integrated and circular U.S. titanium metal supply chain, our highest priority is to rapidly scale a profitable titanium scrap-to-metal business in Virginia.

Investment Capital for Commercialization

In June 2023, we raised ~US$13.5 million in an equity placement led by our two largest shareholders, Fidelity Management & Research Company and Fidelity International. In October, we received a Letter of Interest from the U.S. Export-Import Bank for the provisional sum of US$11.5 million. In November 2023, we were advised that we were awarded a US$12.7 million grant from the U.S. Department of Defense under the Defense Production Act Title III for domestic titanium production and successfully raised an additional US$16.7 million in equity from existing investors. Receipt of funding under the DoD grant and the successful equity raise is expected to fund our initial Virginia production scale up which is estimated to cost ~US$21.5 million.

The Year Ahead

This year is set to be a transformative for IperionX as we aim to realize our own “Bessemer Moment”. We are not just aiming to replicate history but to create our own by disrupting the global titanium supply chain with low cost, sustainable and high-performance titanium products.

Our leading technologies, including HAMR and HSPT, have improved and progressed from a decade of advanced development and 2024 will see IperionX commission our large-scale industrial furnace and demonstrate these leading technologies at commercial scale. Our Virginia titanium facility is designed to apply our HAMR and HSPT technologies to produce sustainable, high-quality and high strength titanium metal products at low cost.