Company Shares Updated Details of Terran R Vehicle Architecture

LONG BEACH, Calif. — (BUSINESS WIRE) — April 12, 2023 — Relativity Space, the first company to 3D print rockets and build the largest metal 3D printers in the world, today revealed plans for Terran R, its reusable, 3D printed, medium-to-heavy lift orbital launch vehicle. Building on over seven years of Relativity Space’s experience, learnings, and momentum gathered through its Terran 1 program – the world’s first 3D printed rocket to fly and reach space – Relativity is accelerating the company’s focus on Terran R to meet significant and growing market demand. Terran R also represents a large leap towards Relativity’s mission to build humanity’s multiplanetary future, eventually offering customers a point-to-point space freighter capable of missions from the Earth to the Moon, Mars, and beyond.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230412005568/en/

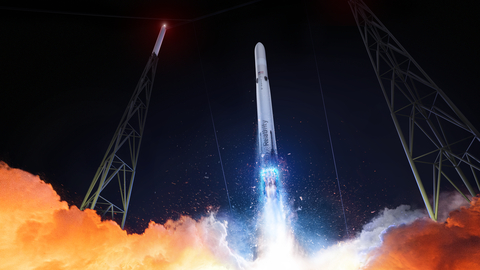

Terran R rocket clearing Launch Complex 16 in Cape Canaveral, Florida. *rendering (Graphic: Business Wire)

Terran R Architecture

As a two-stage, 270-foot-tall rocket with an 18-foot diameter and a 5-meter payload fairing, Terran R is a customer-centric next-generation launch vehicle designed to meet the needs of commercial companies and government entities sending payloads into LEO, MEO, GEO, and beyond. Terran R's architecture choices enable accelerated development and the ability to deliver a rapidly scaling launch cadence for customers. Terran R will prioritize first stage reusability, with the capability of launching 23,500kg to Low Earth Orbit (LEO) or 5,500kg to a Geosynchronous Transfer Orbit (GTO), both with downrange landing, or up to a maximum payload of 33,500kg to LEO in expendable configuration. Horizontal integration to the vehicle will be supported through a standard Payload Attach Fitting (PAF) interface, with payload integration configurations available for clusters of constellation satellites, single large satellites, or other unique spacecraft. Starting in 2026, Terran R will launch from Space Launch Complex 16, the company’s orbital launch site at Cape Canaveral, Florida.

Designed for rapid reusability and development iteration speed, Terran R is a 3D printed rocket, with initial versions using aluminum alloy tank straight-section barrels in a hybrid manufacturing approach, which allows Relativity to meet the rapid launch and ramp rate timelines necessary to serve overwhelming market demand, including servicing Relativity’s signed customer backlog of $1.65B in Launch Service Agreements (LSAs) and additional several billion dollars in active customer LSA dialogue. Each Terran R requires approximately 6 times more 3D printing by mass than Terran 1. 3D printing technology for Terran R is strategically used to reduce vehicle complexity and improve manufacturability, with continued company focus on redefining what is possible with large scale additive manufacturing after successfully proving the viability of 3D printed rockets with Terran 1. Initially, Terran R will use the same proprietary printed aluminum alloy as flown on Terran 1 with a focus on supply chain scaling. However, a third-generation aluminum alloy, designed for improved performance of an orbital vehicle mission life beyond 20 reusable flights, is in active development, which is accelerated by the aid of artificial intelligence-based alloy discovery tools.

Terran R’s first stage will be outfitted with 13 3D-printed gas generator cycle Aeon R LOx/Methane rocket engines each capable of 258,000 lb. sea level thrust, while its second stage houses a single LOx/Methane Aeon Vac engine with 279,000 lb. vacuum thrust. These engines benefit from Relativity’s advanced experience developing gas generator engines and vehicle stages with the oxygen/methane propellant combination. The engine composition on the first stage is comprised of four outer fixed engines aligned underneath four landing legs, and nine center gimbaled engines, providing enhanced reliability on vehicle ascent with engine-out capability. On both Terran R stages, the LOx propellant tanks are forward of the methane tanks, separated by a printed common dome. Subcooled cryogenic propellants are used on all parts of the vehicle except for the first stage liquid oxygen system, where subcooling is not necessary to meet performance goals. Both stages use a cryogenic helium pressurization system to enable better press authority when engines are not turned on by reducing ullage collapse. The vehicle also features an in-house developed pneumatic pusher stage separation system.

Terran R features two near body-length aero strakes, four unique slider-mechanism landing legs, and four printed actuating grid fins. These features optimize first stage reusability, enabling rapidly scaled launch cadence for customers together with greater payload to orbit and lower costs versus other reusable architectures. Terran R’s innovative first stage architecture allows for a high angle of attack reentry which reduces propellant required for reentry burns, aerodynamic design for better reentry stability and improved control authority, and a passively actuated landing leg deployment system which is elegantly simple, lightweight, and highly operable for rapid reuse. An 18-foot vehicle diameter also aids vehicle stability with lower requirements on landing legs. Terran R will have an electromechanical actuator (EMA)-based engine thrust vector control (TVC) system, and also use EMAs for grid fin control, in addition to in-house developed avionics and flight software. Additionally, the vehicle features a reentry heat shield on the aft end designed for rapid reusability.

Aeon R Engine Design

Terran R’s 3D printed Aeon R engines are designed to use liquid oxygen and liquid methane propellants, be highly reusable, and feature a uniquely high-pressure gas generator cycle driving two turbopumps. Designed and manufactured in-house by Relativity, Aeon R engines are produced with significant advancements in additive manufacturing technology, building on the development of the company’s prior engine, Aeon 1. These new 3D printing capabilities enable the scale required for the higher thrust-class Aeon R engine, continuing to drive part count reductions by designing and printing singular “nodes of simplicity,” streamlining many engine elements into unified prints. This innovative design approach supports lowered costs, lowered engine complexity, greater robustness, rapid iteration, and the speed and scale of production required to serve customers.

Already a focus of significant development and testing efforts for the last two years, Aeon R benefits from the heritage of its smaller predecessor, Aeon 1, which is used onboard Relativity’s Terran 1 rocket. Migrating many of the same thoughtful propulsion system architecture decisions from Aeon 1 to Aeon R has unlocked a high rate of iterative design and fast-tracked much of the Aeon R test program. Since mid-2022, Relativity has been underway testing all Aeon R combustion devices at NASA Stennis Space Center – including the main Thrust Chamber Assembly (TCA), gas generator (GG), and gas-gas ignition system – at full scale and 100% power with high combustion efficiency. All engine active valves are developed in-house, with all valves produced, successfully actuated, and in development testing. In February 2023, the company completed its first full build of an Aeon R engine, and turbopump testing will begin in the coming months ahead of full engine testing this year.

Designed for Reusability from Day One

From day one, Terran R was intentionally designed for reusability. The company intends to design major parts of the vehicle for 20 reuses right away, with strategic development of reusability criteria and rapid learning from flight data to continuously improve through successive vehicle block upgrades. Focusing on our customer’s needs for urgent, disruptive, relevant, and diversified launch supply in the medium-to-heavy payload market, we chose to prioritize optimizing for first stage reuse initially. Each early flight of Terran R will seek to deliver customer payloads to orbit reliably. Then, after vehicle ascent, Max-Q, MECO, stage separation, and second stage ignition - with the customer payload well on its way to orbit - the first stage will begin its entry, landing, and reuse journey.

First Stage Reuse Process

Shortly after stage separation, the first stage of Terran R will perform a slow flip maneuver using its cold gas Reaction Control System (RCS). Grid fins deploy, followed by igniting engines to complete entry burns, slowing velocity and reducing peak loads and heating. Vehicle aerosurfaces and strakes are uniquely designed to enable high angle of attack on entry. This reduces the payload penalty for reuse with less propellent used on entry burns. Additionally, unique aerodynamic features result in a more stable entry profile with controlled flow separation around the vehicle. Terran R is designed for atmospheric entry with grid fin control. The vehicle will then ignite engines for a landing burn and command the leg slider mechanism to open, which will then passively deploy with the aid of aerodynamics. The first stage will then touchdown on a downrange ship in the ocean. Once the first stage has completed its reentry, it will go for inspection, refurbishment, and recertification for its next flight from Cape Canaveral.