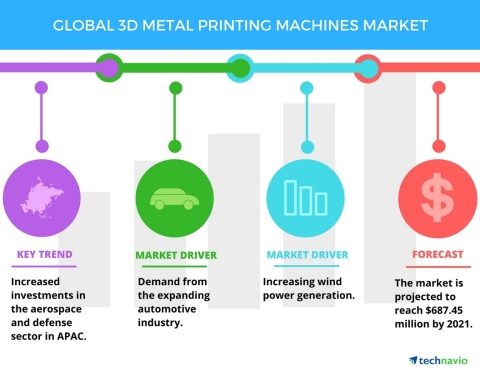

LONDON — (BUSINESS WIRE) — October 26, 2017 — Technavio’s latest market research report on the global 3D metal printing machines market provides an analysis of the most important trends expected to impact the market outlook from 2017-2021. Technaviodefines an emerging trend as a factor that has the potential to significantly impact the market and contribute to its growth or decline.

This press release features multimedia. View the full release here: http://www.businesswire.com/news/home/20171026005906/en/

Technavio has published a new report on the global 3D metal printing machines market from 2017-2021. (Graphic: Business Wire)

One of the key factors resulting in the growth of the 3D metal printing machines market is the demand from the expanding automotive industry. While manufacturing automotive vehicles, manufacturers must consider many factors. Some of the factors include energy efficiency, reduced COâ‚‚ emissions, reducing cost and yet innovating new models. 3D metal printing offers an effective solution to these considerations.

This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing

Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free.

The top three emerging trends driving the global 3D metal printing machines market according to Technavio research analysts are:

- Increased investments in the aerospace and defense sector in APAC

- Increased gas turbine installation in the US

- Increased demand for dental implantation

Looking for more information on this market? Request a free sample report

Technavio’s sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more.

Increased investments in the aerospace and defense sector in APAC

Engine structures for the aerospace industry are created using 3D printing technology. This technique has been gaining popularity among aircraft manufacturers as the structures created by using this technique are lightweight and steady. This has led to manufacturers readily adopting this technology. In 2014, Airbus delivered its first aircraft that had parts incorporated using a 3D metal printer. Premium AEROTEC, an Airbus subsidiary, started production in its titanium 3D printing facility. In April 2017, Airbus, in collaboration with the Chemnitz University of Technology in Germany, developed hydraulic valves using 3D printing technology. The valve is 35% lighter in weight and is made up of titanium. Growth prospects are improved due to the quick adoption of this technology.

According to Gaurav Mohindru, a lead analyst at Technavio for engineering tools, “There has been an increase in the demand for aircraft from the aerospace and defense sector. Growing population, urbanization, and growth in air traffic have attributed to the expansion of the aerospace sector, in turn contributing to the increasing demand for aircraft. Several countries in APAC such as India and China, have experienced growth in air traffic and this has led to aircraft manufacturers showing an upward trend.”

Increased gas turbine installation in the US

Gas turbine blades are printed using 3D metal printing technique. The demand for 3D metal printing and 3D metal printing machines is escalating due to the rising demand for gas turbines, especially in the US. Gas turbine blade manufacturing is gaining various technological investments. For instance, Siemens got engineers from Lincoln, Berlin, and the Swedish municipality of Finspong to develop the process chain and test a new additively manufactured blade design. The blades thus manufactured were installed in a 13 MW SGT-400 type industrial gas turbine. A breakthrough in the gas turbine market is achieved due to such developments in 3D printing technology.

There has been an increase in gas turbine installations because the US has witnessed an increase in natural gas power production, which is mainly attributed to the falling natural gas prices. The decline in natural gas prices was a result of the expansion of production of natural gas near shale formations. The share of natural gas in power generation is also expected to increase.

Increased demand for dental implantation

Dental frames that are used for implantations can be created using 3D metal printing machines. Rising awareness and an increase in disposable income have initiated global trends in healthcare. Consequently, this has resulted in increased demand for dental care products and thus for 3D metal printing devices. The increased incidence of oral diseases and a rise in the number of dental procedures are the major factors fueling the demand for dental products. Technological advancements such as the introduction of 3D metal printing have been introduced in dental care. Restoration procedures using amalgam fillings are experiencing a setback due to the introduction of bridges and crowns.

“Cosmetic dentistry has been accepted by the American culture. Increasing awareness about dental prosthetic and implant consumables has increased the volume of dental procedures. Implantation is a quick process, and the implantation success rate is around 95%, which is why it has become a preferable treatment among patients. No other procedure offers such natural and unobtrusive fit and feel to patients. This popularity of dental implants has increased the demand for 3D metal printing machines for this application,” says Gaurav.

Browse Related Reports:

- Global 3D Laser Cutting Machine Market 2017-2021

- Global Safety Air Guns and Air Nozzles Market 2017-2021

- Global Heating Equipment Market 2017-2021

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio’s report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio’s comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

If you are interested in more information, please contact our media team at Email Contact.

View source version on businesswire.com: http://www.businesswire.com/news/home/20171026005906/en/