MONTREAL, May 02, 2024 (GLOBE NEWSWIRE) -- PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR) (OTCQX: PYRGF) (FRA: 8PY), a high-tech company (the “Company” or “PyroGenesis”) that designs, develops, manufactures and commercializes advanced plasma processes and sustainable solutions which are geared to reduce greenhouse gases (GHG) and address environmental pollutants, is pleased to announce today that it has been advised by its client, Progressive Planet, that the latest series of compressive strength tests on its PozPyro green cement additive product reveal impressive results, posting strength comparisons significantly above the acceptable standard for similar material. PozPyro enhances the strength of concrete as a replacement for fly ash, which is in diminishing supply.

PozPyro, a cement alternative, is being developed in collaboration with Progressive Planet as a supplementary cementing material (SCM) designed to partially replace traditional Portland Cement. Of note, Portland Cement emits substantial amounts of CO2 during its production. PozPyro, on the other hand, is created by using a PyroGenesis plasma-based process that transforms quartz silica, a widely available material, into a SCM (PozPyro), without off-gassing CO2 during the production process. This innovation comes at a time when the cement industry seeks more sustainable practices without compromising quality or performance.

“Quartz silica is one of the most abundant materials in the earth’s crust,” said P. Peter Pascali, President and CEO of PyroGenesis. “The ability to economically convert it into PozPyro could offer a new supply of material to compensate for the diminishing supply of fly ash, a common SCM, which, by the way, is generated by the same coal fired power plants which are being targeted for shut down in Canada by 2030.”

According to Progressive Planet’s news release today, concrete producers are looking for SCMs that (i) increase the compressive strength of their mix while at the same time (ii) lowering their carbon footprint without sacrificing workability.

WORKABILITY

The workability of cement is measured by water demand and is a measure of its ease of use in various concrete applications. The smaller the water demand number, the better the reading. A passing water demand number must be less than 115% of the water demand of the control mix.

The water demand for PozPyro was between 99% and 109% for all test batches and as such PozPyro demonstrated excellent workability.

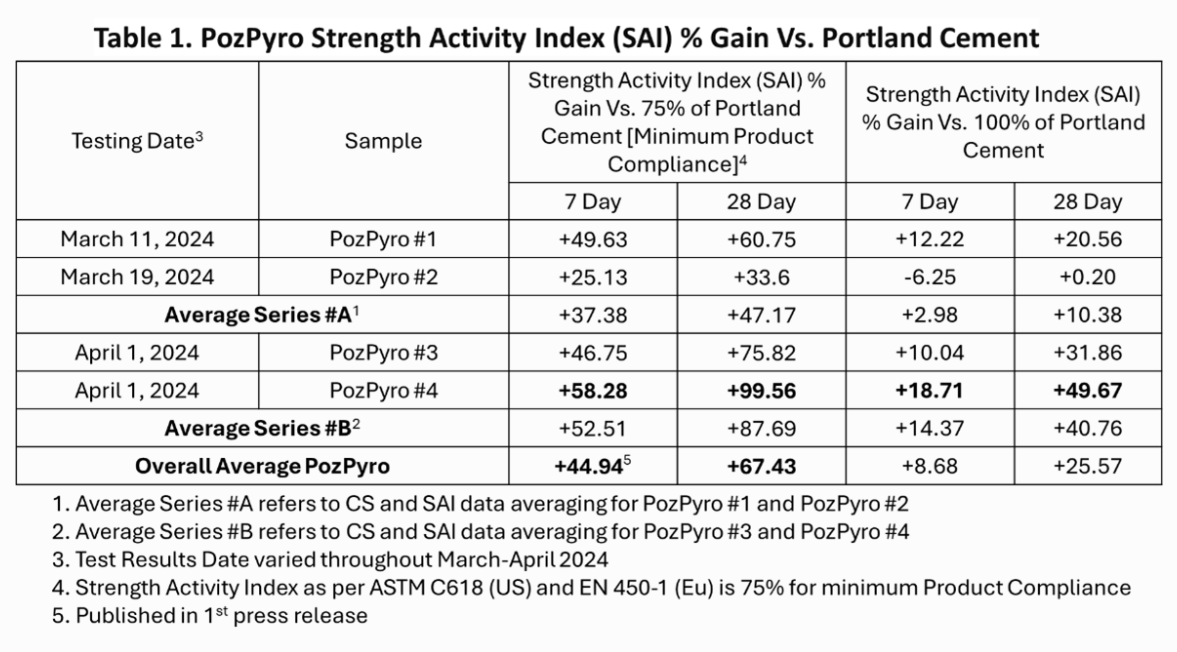

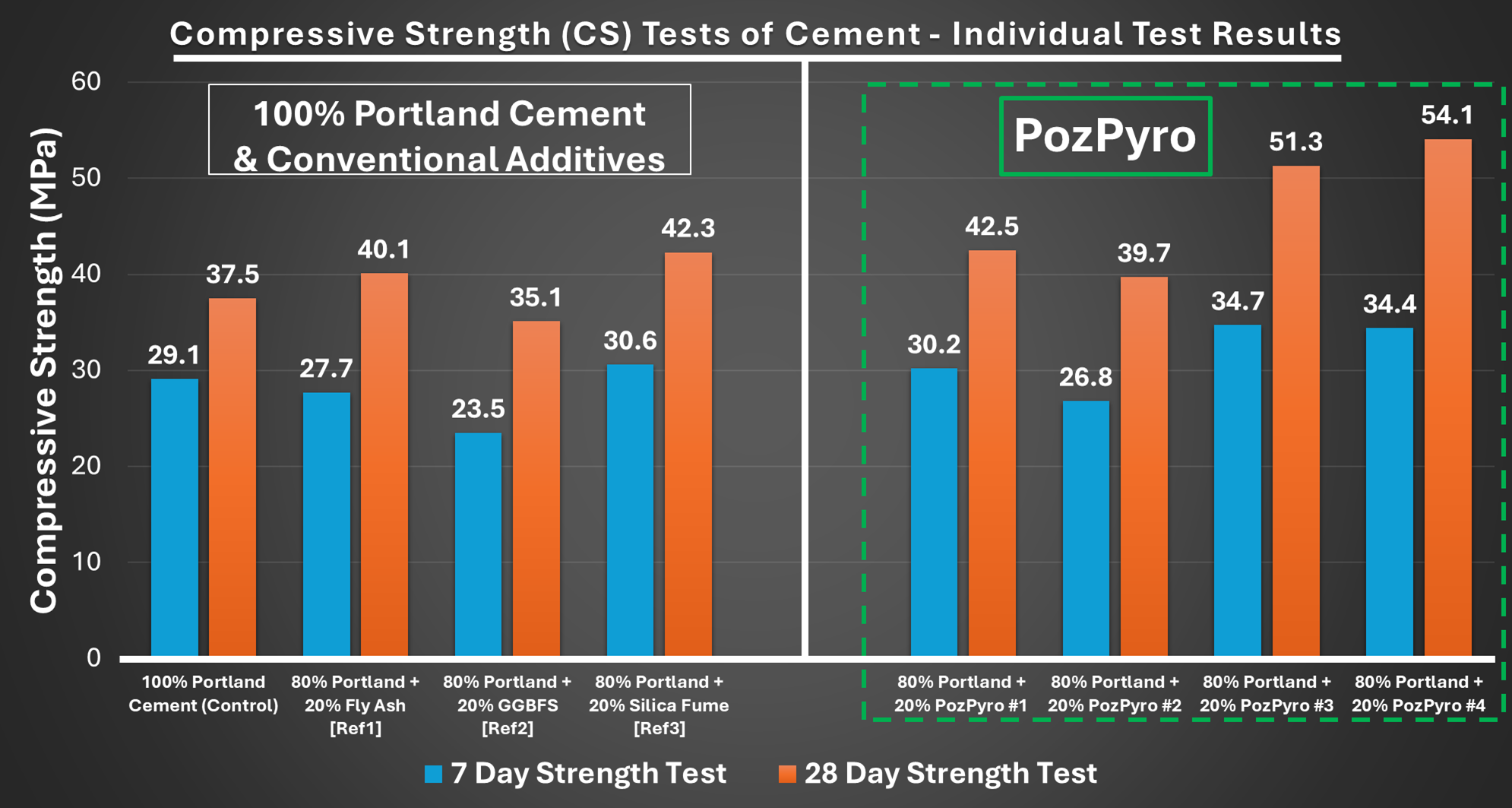

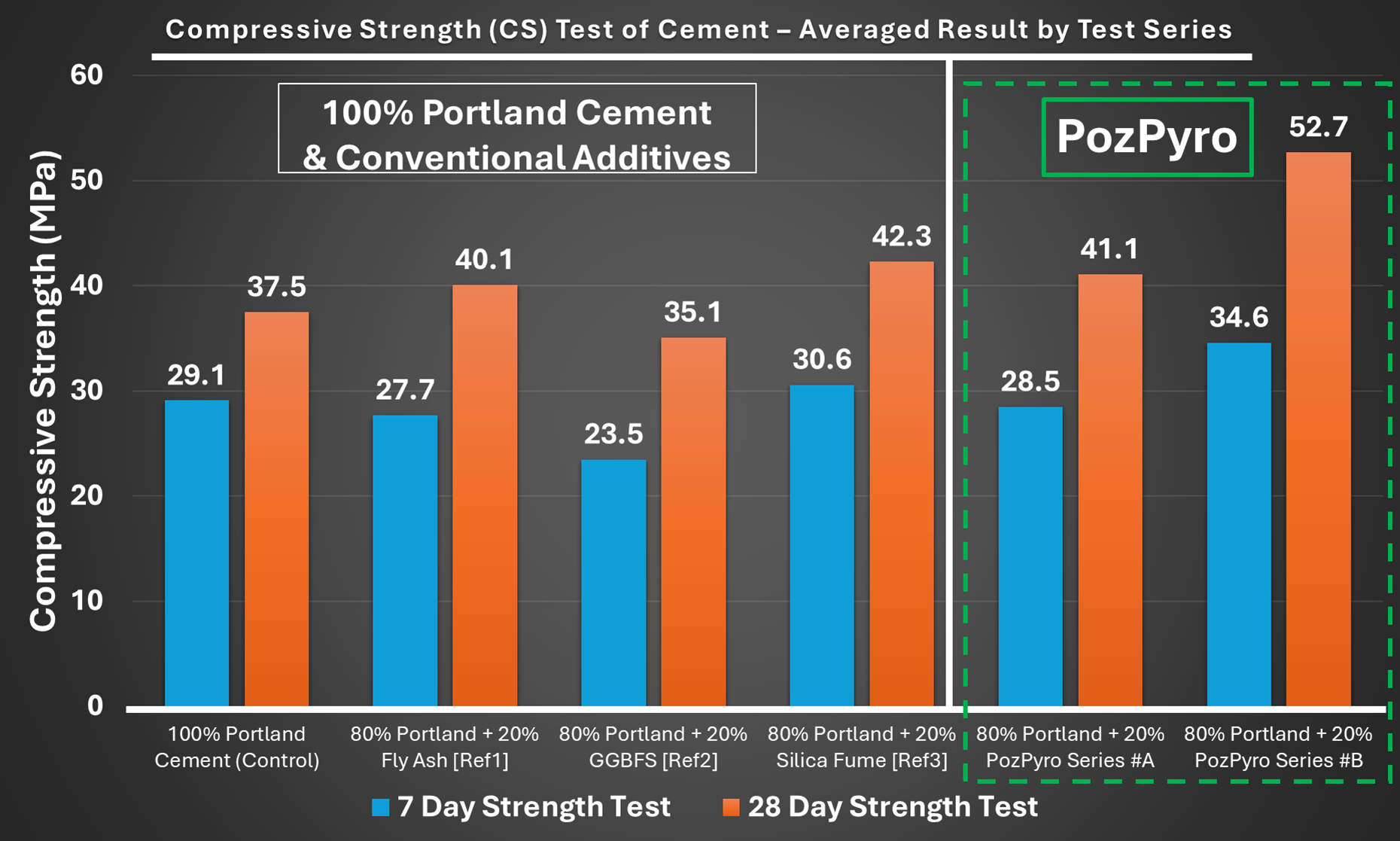

STRENGTH ACTIVITY INDEX (SAI)

The SAI is an industry standard for measuring the compressive strength of cement mortar cubes. As announced in a press release on April 11, 2024, the results of the 7-day testing that showed an approximate average +45% SAI gain across four tests against the minimum target value.

In the 28-day tests announced today, Portland Cement was used as the control product, with varied compressive strengths between 35.26 and 39.62 megapascals (MPa) depending on the test.

These tests were conducted in two series, A and B, with two tests in each series, using different input variables to test for optimized results.

TESTING AGAINST MINIMUM COMPLIANCE (75% PORTLAND CEMENT MPA)

For SAI tests, a cement additive product test is acceptable at a minimum strength of 75% of the control product strength.i For one Series B test, the Portland Cement control achieved a compressive strength value of 36.18 MPa at 28 days. An additive product would therefore be acceptable based on achieving 27.14 MPa (equating to 75% of the Portland Cement control strength).

The results for the individual Series B test showed a blend of Portland Cement containing 20% PozPyro far surpassed this target, achieving a peak result of 54.15 MPa – a result 99.56% higher than the minimum acceptable value.

The overall average gain for all tests in both series A and B was +67.43% against the minimum compliant for an acceptable cement additive product.

TESTING AGAINST MAXIMUM COMPLIANCE (100% PORTLAND CEMENT MPA)

When compared to a 100% value of Portland Cement alone, this same Series B PozPyro/Portland Cement blend test surpassed even the full-strength value of the Portland Cement control product by up to 49.67%.

The overall average gain for all tests in both series A and B was +25% against the maximum product compliance for an acceptable cement additive product. This result means that the PozPyro material, when added to Portland Cement at a 20%/80% blend, outperformed a cement-only Portland Cement control in strength tests by 25%.

“These 28-day test results confirm the impressive results achieved by the previous 7-day tests, and underscore yet again the potential transformative nature of plasma in producing materials, in both an economically and environmentally beneficial manner, that are key to heavy industry,” said P. Peter Pascali, President and CEO of PyroGenesis. “Not only were we able to far surpass the minimum acceptable product standard compared to 75% of the control, but when compared to a full value of the control the PozPyro green cement additive showed a 49.67% gain. In other words, these tests suggest that not only can PozPyro potentially outperform other traditional cement additive products in strength, it has the potential to directly outperform pure cement alone. As I’ve stated before, the cement industry is a key target for us, and we have high expectations for the PozPyro green cement additive material.”

Image 1: A comparison of the four individual Series A and Series B strength tests, measured at 7- and 28-days in megapascals (MPa) of a 20% PozPyro/80% Portland Cement blend against a 100% pure Portland Cement control, a 20% fly ash blend, a 20% ground granulated blast-furnace slag (GGBFS) blend, and a 20% silica fume blend produced using traditional methods.

Steve Harpur, CEO of Progressive Planet, commented on the results over the last month during which Progressive Planet prepared four separate batches of cement mortar cubes to test, under the American Society for Testing and Materials (“ASTM”) testing protocol, at both 7 and 28 days for compressive strength: “These results were exceptional and provide us the technical confidence to take the next steps to bring this product to market. In the Pacific Northwest alone, over one million tons of fly ash will cease to be generated by the summer of 2025 at which time two massive thermal coal to energy facilities will have finished converting from burning coal to natural gas.”

Image 2: A comparison of the Series A and Series B strength tests, measured at 7- and 28-days in megapascals (MPa) of a 20% PozPyro/80% Portland Cement blend, using averages of each of two tests within both Series A and Series B, against 100% pure Portland Cement control, 20% fly ash blend, 20% ground granulated blast-furnace slag (GGBFS) blend, and 20% silica fume blend.