New 1-meter Sapphire XC to Begin Shipping in Late Q3 With the First Systems Being Delivered to Several Aerospace Companies

CAMPBELL, Calif. — (BUSINESS WIRE) — June 16, 2022 — Velo3D, Inc. ( NYSE: VLD), a leading metal additive manufacturing technology company for mission-critical parts, today announced a new addition to its Sapphire family of printers with the Sapphire XC 1MZ. The new printer allows customers to print parts one meter in height—with a total build volume that is twice that of the Sapphire XC and nine times larger than the original Sapphire—increasing the addressable use-cases of Velo3D’s end-to-end metal additive manufacturing solution.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220616005179/en/

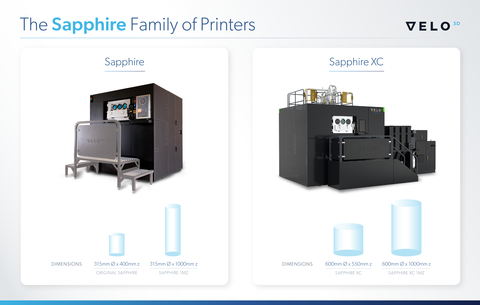

The Sapphire family of printers includes four unique system variations. Every Sapphire printer is fully compatible, delivering repeatable, consistent outcomes across any machine. As production limits are reached, customers can scale by simply adding another printer to their fleet. (Graphic: Business Wire)

Sapphire XC 1MZ continues Velo3D’s legacy of delivering leading-edge performance for metal additive manufacturing technology and has the largest laser powder bed fusion print volume from a leading manufacturer. The Sapphire XC 1 MZ system combines Velo3D’s innovative geometric capabilities with the repeatable, standardized processes and validated material properties necessary to achieve distributed manufacturing in a larger format. The Sapphire XC 1MZ was designed based on feedback from customers in the aerospace, energy, and defense industries, with the first systems expected to be delivered to several aerospace companies in late Q3 2022.

“Without advanced metal additive manufacturing it would be difficult to impossible to build many of the technologies that are shaping the future of our world,” said Benny Buller, Velo3D CEO and Founder. “Our innovative customers have a clear understanding of how the technology can unlock new capabilities for their businesses and transform their product offerings. New systems, like the Sapphire XC and Sapphire XC 1MZ, support that transformation by significantly increasing throughput up to 400% and lowering costs by up to 75% compared to the original Sapphire.”

Features of the Sapphire XC 1MZ include:

- The largest build volume of any laser powder bed fusion printer in its class—600 mm x 1,000 mm—nine times larger than the original Sapphire and 30% larger than printers from other leading manufacturers

- Eight 1-kilowatt lasers

- An integrated, end-to-end manufacturing solution including Flow print preparation software and Assure quality assurance software

- The Intelligent Fusion manufacturing process that has been proven in production on Sapphire and Sapphire XC for consistent, repeatable results across different printers

- Faster non-contact recoater to decrease the time required between build layers

- Increased throughput of up to 400% over the original Sapphire and Sapphire 1MZ printers

The Sapphire XC 1MZ will be available in all the materials currently offered by Velo3D, including Aluminum F357, Amperprint® 0233 Haynes® 282, GRCop-42, Hastelloy C22, Hastelloy X, Inconel® 625, Inconel® 718, Scalmalloy, and Titanium 6AI-4V Grade 5.

The Sapphire family of printers is comprised of four unique system variations that are fully compatible with one another, running the same processes across all printers in a way that delivers consistent results on any machine. This means that as customers validate one printer for production use, it is simple to add additional printers to increase productivity. The original Sapphire printer is capable of printing parts that are 315 mm in diameter and 400 mm in height. The Sapphire 1MZ prints at 315 mm in diameter and 1 meter in height. The Sapphire XC, which began shipping in Q4 2022, has a build volume of 600 mm in diameter by 550 in height.

The Sapphire XC 1MZ combines the large diameter of the Sapphire XC with the 1-meter build height of the Sapphire 1MZ to achieve the largest print volume of any laser powder bed fusion printer from a leading manufacturer. To learn more about the Sapphire XC 1MZ, visit the Velo3D blog or download the data sheet.

About Velo3D:

Velo3D is a metal 3D printing technology company. 3D printing—also known as additive manufacturing (AM)—has a unique ability to improve the way high-value metal parts are built. However, legacy metal AM has been greatly limited in its capabilities since its invention almost 30 years ago. This has prevented the technology from being used to create the most valuable and impactful parts, restricting its use to specific niches where the limitations were acceptable.

Velo3D has overcome these limitations so engineers can design and print the parts they want. The company’s solution unlocks a wide breadth of design freedom and enables customers in space exploration, aviation, power generation, energy and semiconductor to innovate the future in their respective industries. Using Velo3D, these customers can now build mission-critical metal parts that were previously impossible to manufacture. The end-to-end solution includes the Flow print preparation software, the Sapphire family of printers, and the Assure quality control system—all of which are powered by Velo3D’s Intelligent Fusion manufacturing process. The company delivered its first Sapphire system in 2018 and has been a strategic partner to innovators such as SpaceX, Honeywell, Honda, Chromalloy, and Lam Research. Velo3D has been named to Fast Company’s prestigious annual list of the World’s Most Innovative Companies for 2021. For more information, please visit Velo3D.com, or follow the company on LinkedIn or Twitter.

Forward-Looking Statements

This press release includes “forward-looking statements” within the meaning of the “safe harbor” provisions of the Private Securities Litigation Reform Act of 1996. The Company’s actual results may differ from its expectations, estimates and projections and consequently, you should not rely on these forward-looking statements as predictions of future events. Words such as “expect”, “estimate”, “project”, “budget”, “forecast”, “anticipate”, “intend”, “plan”, “may”, “will”, “could”, “should”, “believes”, “predicts”, “potential”, “continue”, and similar expressions are intended to identify such forward-looking statements. These forward-looking statements include, without limitation, the Company’s expectations, hopes, beliefs, intentions or strategies for the future. These forward-looking statements involve significant risks and uncertainties that could cause the actual results to differ materially from the expected results. You should carefully consider the risks and uncertainties described in the documents filed by the Company from time to time with the SEC. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Most of these factors are outside the Company’s control and are difficult to predict. The Company cautions not to place undue reliance upon any forward-looking statements, including projections, which speak only as of the date made. The Company does not undertake or accept any obligation to release publicly any updates or revisions to any forward-looking statements to reflect any change in its expectations or any change in events, conditions or circumstances on which any such statement is based.

VELO, VELO3D, SAPPHIRE, and INTELLIGENT FUSION, are registered trademarks of Velo3D, Inc.; and WITHOUT COMPROMISE, FLOW and ASSURE are trademarks of Velo3D, Inc. All Rights Reserved © Velo3D, Inc.

Amperprint® 0233 Haynes® 282 Powder is produced by Höganäs under License from Haynes International, Inc.

View source version on businesswire.com: https://www.businesswire.com/news/home/20220616005179/en/

Contact:

Media Contact:

Dan Sorensen, Senior Director of Public Relations

press@velo3d.com

Investor Relations:

Bob Okunski, VP Investor Relations

investors@velo3d.com