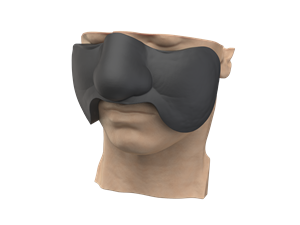

- Latest innovation for company’s VSP solutions is the only complete design and production service available for radiation therapy professionals

- 3D printing of the patient-specific shape reduces air gaps and improves efficacy of treatment

ROCK HILL, S.C., April 21, 2022 (GLOBE NEWSWIRE) -- Today, 3D Systems (NYSE:DDD) announced its entry into the radiation oncology market with FDA 510(k) clearance of VSP ® Bolus, a solution designed to deliver high-quality patient-specific radiotherapy treatment accessories. As the latest addition to the company’s VSP portfolio of personalized medical devices, VSP Bolus is the only solution on the market that offers a full design and production service based on the patient’s treatment plan. As a result, radiotherapy providers do not need specialized design software and expertise, allowing them to focus directly on patient treatment and care. 3D Systems’ deep experience in additive manufacturing of medical devices enables the company to deliver 3D-printed, biocompatible patient-specific boluses that can improve therapy modulation as well as patient comfort.

Approximately 50% of patients diagnosed with cancer will receive radiotherapy as part of their treatment. To help target the radiation during treatment, the provider (e.g., medical physicist, dosimetrist, radiation oncologist) will use a bolus—a flexible device that conforms to the patient’s skin. Off-the-shelf boluses can often leave gaps between the device and the patient’s anatomy, which can result in insufficient dosing and may also expose adjacent anatomy to undesired radiation. With VSP Bolus, 3D Systems can design and deliver boluses that conform to a wide range of anatomies. The process begins with the patient’s imaging data and input from the radiotherapy professional. Using this information, VSP Bolus is designed at the requested material thickness to optimize the radiotherapy targeting. With these capabilities built into the solution, radiotherapy professionals are freed from the time-consuming task of creating the design and fabricating the accessory themselves. Once designed, 3D Systems’ engineers employ the company’s additive manufacturing solutions to produce a high-quality bolus from a soft material that contours to the patient’s anatomy, enabling more efficacious treatment and a more comfortable experience.

“Our new VSP Bolus product expands our capabilities to address yet another incredibly important application for personalized healthcare,” said Menno Ellis, executive vice president, healthcare solutions, 3D Systems. “While radiotherapy has become recognized as a common course of treatment for cancer diagnoses, each case is as unique as each patient. Blending the experience of our biomedical engineers, our biocompatible materials, 3D printing technology, and best-in-class digital workflows, we are able to both design and produce patient-specific devices to help improve the delivery of radiotherapy treatment.”

As a pioneer in personalized healthcare solutions, 3D Systems has worked with surgeons over the last decade to plan more than 140,000 patient-specific cases, and manufacture more than two million implants and instruments for 100+ CE-marked and FDA-cleared devices from its world-class, FDA registered, ISO 13485-certified facilities in Littleton, Colorado, and Leuven, Belgium. 3D Systems will showcase its solutions, including VSP Bolus, at the RSNA Medical 3D Printing in Practice event to be held April 22-24 in Chicago, Illinois. For more information, please visit the company’s website.

Forward-Looking Statements

Certain statements made in this release that are not statements of historical or current facts are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward-looking statements. In many cases, forward-looking statements can be identified by terms such as "believes," "belief," "expects," "may," "will," "estimates," "intends," "anticipates" or "plans" or the negative of these terms or other comparable terminology. Forward-looking statements are based upon management’s beliefs, assumptions, and current expectations and may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings "Forward-Looking Statements" and "Risk Factors" in the company’s periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements. Although management believes that the expectations reflected in the forward-looking statements are reasonable, forward-looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward-looking statements included are made only as of the date of the statement. 3D Systems undertakes no obligation to update or revise any forward-looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances or otherwise, except as required by law.

About 3D Systems

More than 30 years ago, 3D Systems brought the innovation of 3D printing to the manufacturing industry. Today, as the leading additive manufacturing solutions partner, we bring innovation, performance, and reliability to every interaction - empowering our customers to create products and business models never before possible. Thanks to our unique offering of hardware, software, materials, and services, each application-specific solution is powered by the expertise of our application engineers who collaborate with customers to transform how they deliver their products and services. 3D Systems’ solutions address a variety of advanced applications in healthcare and industrial markets such as medical and dental, aerospace & defense, automotive, and durable goods. More information on the company is available at

www.3dsystems.com.

A photo accompanying this announcement is available at https://www.globenewswire.com/NewsRoom/AttachmentNg/807c71e9-1aaa-4382-aa6c-80f09a2b55e4

Investor Contact: inveestor.relations@3dsystems.com Media Contact: press@3dsystems.com