- New patent-pending process developed by ExOne and Ford Motor Co. for binder jetting 6061 aluminum, one of the most commonly used aluminum alloys in the world, delivers final parts with 99% density and material properties comparable to traditional manufacturing

- Sintering precision parts in aluminum can unlock new benefits in manufacturing, such as new lightweight part designs that improve system design and performance

- This rapid and reliable process for future production of aluminum parts is much faster than other 3D printing methods and capable of scaling to the volumes needed for automotive use

- Ford and ExOne are actively working on designs to use the new material and process

NORTH HUNTINGDON, Pa. — (BUSINESS WIRE) — March 11, 2021 — In a project co-funded by Ford Motor Company and the ExOne Company, a team of engineers, material scientists, and manufacturing experts has developed a patent-pending process for rapid and reliable binder jet 3D printing and sintering of aluminum that delivers properties comparable to die casting.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20210311006007/en/

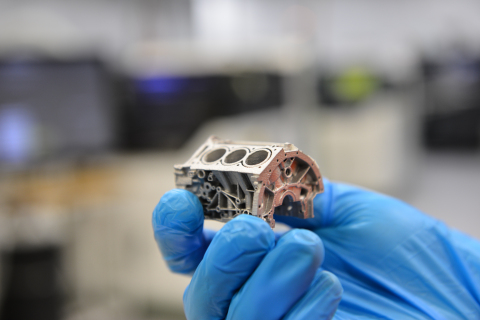

This aluminum 6061 engine block model demonstrates the high resolution and geometric control that can be produced in a new patent-pending binder jet 3D printing and sintering process developed by ExOne and Ford Motor Co. (Photo: Business Wire)

Delivering a commercially viable achievement in this area has evaded researchers for more than a decade. Collaborative and individual patents are expected to be filed by Ford and ExOne as a result of this ongoing project.

Some aluminum alloys can be 3D printed today using lasers, but the process is much slower than the one developed by Ford and ExOne. The new process is expected to increase Ford’s efficiency by allowing the company to affordably produce complex parts uniquely designed for additive manufacturing, which enables size and weight reductions, part consolidation, and performance improvements.

“This is a breakthrough in making 3D printed and sintered parts for the auto industry,” said Harold Sears, Ford technical leader for additive manufacturing. “While the 3D-printing process is very different than stamping body panels, we understand the behavior of aluminum better today, as well as its value in light-weighting vehicles. High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminum that previously weren’t possible. It’s really opening doors for other opportunities.”

“Developing a fast, affordable, and easy way to 3D print aluminum with traditional material properties is a critical step toward light-weighting more products and delivering a more sustainable future,” said John Hartner, ExOne CEO. “Our world-class engineers and scientists are focused on solving the toughest problems with 3D printing technology, and this achievement is a real win for all of us.”

The new innovation came about through the process of binder jetting, widely regarded as the fastest method of metal 3D printing for high-volume output. It uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand, or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. The heating process reinforces the strength and integrity of the metal, and while the process for sintering stainless steel is well understood, achieving high densities greater than 99 percent is an industry breakthrough for aluminum.

The Ford-ExOne joint development project was first initiated in 2019. Ford has led the final material and repeatability testing to verify its accuracy. The cross-functional Ford-ExOne team is actively working on designs to use the new material and process.

The relationship between Ford and ExOne goes back to the early 2000s, when Ford purchased several of ExOne’s first industrial sand 3D printers in the United States to create sand molds and cores for metal casting. ExOne 3D printers are among a wide range of technologies featured in Ford’s Advanced Manufacturing Center in Redford, Mich., with additional ExOne printers in Ford’s U.K. facilities.

For more information about today’s announcement, such as high-resolution photos, video and more information about the technology, visit www.exone.com/aluminum.

About ExOne

ExOne (Nasdaq: XONE) is the pioneer and global leader in binder jet 3D printing technology. Since 1995, we’ve been on a mission to deliver powerful 3D printers that solve the toughest problems and enable world-changing innovations. Our 3D printing systems quickly transform powder materials — including metals, ceramics, composites and sand — into precision parts, metalcasting molds and cores, and innovative tooling solutions. Industrial customers use our technology to save time and money, reduce waste, improve their manufacturing flexibility, and deliver designs and products that were once impossible. As home to the world’s leading team of binder jetting experts, ExOne also provides specialized 3D printing services, including on-demand production of mission-critical parts, as well as engineering and design consulting. Learn more about ExOne at www.exone.com or on Twitter at @ExOneCo. We invite you to join with us to #MakeMetalGreen™.

View source version on businesswire.com: https://www.businesswire.com/news/home/20210311006007/en/

Contact:

Sarah Webster

724.516.2336

sarah.webster@exone.com

Doug Braunsdorf

1.646.899.7687

doug.braunsdorf@bcw-global.com