New METHOD Carbon Fiber Editions Print Metal Replacement Parts with High Strength and Accuracy;

The METHOD Platform Further Expands to Support More Materials, Applications, and Markets

BROOKLYN, N.Y. — (BUSINESS WIRE) — May 19, 2020 — MakerBot, a global leader in 3D printing and subsidiary of Stratasys (Nasdaq: SSYS), moves into the next level of 3D printing with the launch of the METHOD Carbon Fiber Editions. The new METHOD Carbon Fiber Editions are designed to enable engineers to print stronger and more accurate parts for manufacturing tools, jigs and fixtures, and end-use production, and can be used to print metal replacement parts in some applications.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20200519005546/en/

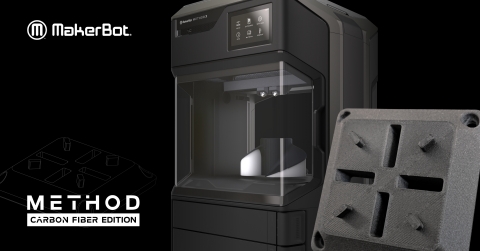

MakerBot METHOD Carbon Fiber Edition (Photo: Business Wire)

The latest additions to the METHOD platform, the METHOD Carbon Fiber Editions print carbon fiber reinforced nylon that is optimized for high strength and heat resistance. The new METHOD and METHOD X Carbon Fiber Editions come pre-configured with a new composite extruder that is optimized to handle abrasive materials. The new extruder, which is also available as an upgrade for the METHOD and METHOD X 3D printers, has hardened metal drive gears, a metal filament switch, and an interchangeable hardened steel nozzle. It can print MakerBot Nylon Carbon Fiber material and all other model materials supported on the METHOD platform.

The new MakerBot Nylon Carbon Fiber material is an ideal lightweight alternative to metal for structural applications such as vehicular brackets and inspection gauges, manufacturing tools such as robotic end effectors, and under-hood applications. Due to its strong thermal and mechanical properties, carbon fiber is frequently used in manufacturing, automotive, and aerospace industries. Used as an alternative to metal parts, carbon fiber can help reduce costs and increase overall efficiencies for companies.

“Nylon carbon fiber is one of the most in-demand and exciting classes of materials. Its high strength, heat resistance, and stiffness properties make it ideal for printing metal replacement parts, helping reduce costs and increase overall efficiency for companies,” said Nadav Goshen, President and CEO, MakerBot. “With the launch of METHOD Carbon Fiber, we are making composite 3D printing more accessible to more users than ever before and opening the door to new applications. METHOD Carbon Fiber is the latest addition to the rapidly growing METHOD 3D printing platform.”

METHOD’s heated chamber produces strong manufacturing-grade nylon carbon fiber parts with superior surface finish. Users can print complex geometries with internal cavities using MakerBot’s PVA soluble support material and anneal the final part for extra strength with METHOD’s new heated chamber annealing feature. With the METHOD X Carbon Fiber Edition, users can print complex geometries using Stratasys® SR-30™ soluble supports for an even better surface finish. Breakaway supports are also available for faster print results. METHOD’s dry-sealed filament bays help to keep the moisture-sensitive nylon carbon fiber material dry, resulting in better print quality and reliability.

MakerBot plans to offer additional composite materials available for the METHOD Carbon Fiber Editions and the composite extruder for METHOD in the future. Since the METHOD X has a higher chamber temperature than METHOD of up to 110°C on the build plane, it will be able to support a wider range of high-performance composite materials in the future. The METHOD Carbon Fiber Editions, MakerBot Nylon Carbon Fiber material, and the composite extruder are expected to begin shipping in June 2020.

The METHOD platform features industrial 3D printing capabilities that make it ideal for printing with advanced, engineering-grade materials. The combination of a heated chamber, ultra-rigid steel frame, sealed material bays, performance extruders, and dissolvable supports enable engineers to print consistently accurate parts. METHOD offers a diverse portfolio of materials for a variety of engineering applications. MakerBot materials include Nylon Carbon Fiber, PC-ABS, PC-ABS FR, ABS, ASA, Nylon, PETG, Tough, PLA, and support materials SR-30 and PVA. Additionally, with the availability of the MakerBot LABS extruder for METHOD, users can print with more industrial materials from leading material suppliers.

For more information, visit www.makerbot.com/carbon.

MakerBot, MakerBot LABS, METHOD, METHOD X, and Tough are registered trademarks or trademarks of MakerBot Industries, LLC in the United States and/or other countries. Stratasys and SR-30 are registered trademarks or trademarks of Stratasys, Inc. in the United States and/or other countries. All other trademarks are the property of their respective owners.

About MakerBot

MakerBot, a subsidiary of Stratasys Ltd. (Nasdaq: SSYS), is a global leader in the 3D printing industry. The company helps create the innovators of today and the businesses and learning institutions of the future. Founded in 2009 in Brooklyn, NY, MakerBot strives to redefine the standards for 3D printing for reliability, accessibility, precision, and ease-of-use. Through this dedication, MakerBot has one of the largest install bases in the industry and also runs Thingiverse, the largest 3D printing community in the world.

We believe there's an innovator in everyone, so we make the 3D printing tools that make your ideas matter. Discover innovation with MakerBot 3D printing.

To learn more about MakerBot, visit makerbot.com, the MakerBot blog, Twitter, LinkedIn, or Facebook. Stratasys (the parent company of MakerBot) reserves the right to utilize any of the foregoing social media platforms, including the company's websites, to share material, non-public information pursuant to the SEC's Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

Note Regarding Forward-Looking Statement

The statements in this press release relating to Stratasys’ and/or MakerBot's beliefs regarding the benefits consumers will experience from the METHOD Carbon Fiber Editions, MakerBot Nylon Carbon Fiber material, and Composite Extruder for METHOD are forward-looking statements reflecting management's current expectations and beliefs. These forward-looking statements are based on current information that is, by its nature, subject to rapid and even abrupt change. Due to the risks and uncertainties associated with Stratasys’ business, actual results could differ materially from those projected or implied by these forward-looking statements. These risks and uncertainties include, but are not limited to: the risk that consumers will not perceive the benefits of the METHOD Carbon Fiber Editions, MakerBot Nylon Carbon Fiber material, and Composite Extruder for METHOD to be the same as Stratasys and/or MakerBot does; the risk that unforeseen technical difficulties will delay the availability and/or shipping of the METHOD Carbon Fiber Editions, MakerBot Nylon Carbon Fiber material, and Composite Extruder for METHOD; the risk that sales of the METHOD Carbon Fiber Editions, MakerBot Nylon Carbon Fiber material, and Composite Extruder for METHOD will be adversely impacted, perhaps severely, for a period of unknown duration, by reduced economic activity in worldwide markets as a result of the coronavirus pandemic outbreak; and other risk factors set forth under the caption “Risk Factors” in Stratasys’ most recent Annual Report on Form 20-F, filed with the Securities and Exchange Commission (SEC) on February 26th, 2020. Stratasys and MakerBot are under no obligation (and expressly disclaims any obligation) to update or alter its forward-looking statements, whether as a result of new information, future events or otherwise, except as otherwise required by the rules and regulations of the SEC.

View source version on businesswire.com: https://www.businesswire.com/news/home/20200519005546/en/

Contact:

Press

MakerBot

Bennie Sham

bennie.sham@makerbot.com