- Development collaboration to focus on cemented carbide (WC-Co), used in cutting tools and wear-resistant parts, and tungsten-copper (W-Cu), used in high-voltage electrical applications

- GTP uses the ExOne® Innovent®, an advanced and compact binder jet 3D printer, to manufacture parts in tungsten carbide and other tungsten composites

NORTH HUNTINGDON, Pa. — (BUSINESS WIRE) — October 29, 2019 — The ExOne Company (Nasdaq: XONE), the global leader in industrial sand and metal 3D printers using binder jetting technology, and Global Tungsten & Powders Corp., a global manufacturer of tungsten metal powders, have entered into a collaboration to advance tungsten-based metal 3D printing using binder jetting.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20191029005153/en/

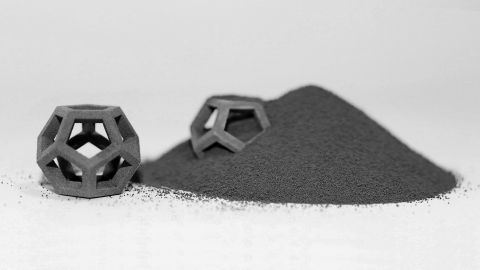

(Photo: Business Wire)

Binder jetting is a 3D printing process that uses a digital file to inkjet a bonding agent into a bed of powder particles, creating a solid part one layer at a time. Compared to other 3D printing processes, binder jetting delivers precision parts at a high rate of speed, making it an ideal approach for serial production.

The new ExOne-GTP collaboration focuses on the development of two metal matrix composites:

- cemented carbide (WC-Co), a material with very high hardness and toughness that is widely used for the production of cutting tools and wear-resistant parts

- copper-tungsten (CuW), which is used in applications where high heat resistance, high electrical and thermal conductivity, and low thermal expansion are needed

“Binder jetting is the 3D printing method of choice for serial production of hard metal parts. Traditionally, tungsten carbide powder is pressed into the desired shape and then sintered to give it strength and density. Instead of costly and timely mold construction, the parts now can be printed directly in the desired shape, still using sintering technology to achieve the final strength. As a market leader in the development and production of high-quality tungsten powders, GTP always stays on top of the latest technology,” said Deborah West, Vice-President Business Unit Refractory & Specialty Powders, GTP. “We are excited to work with ExOne in the development of cutting-edge technology for the additive manufacturing industry.”

Tim Pierce, ExOne Vice President of Metal Commercial Products, added: “Metal 3D printing using our exclusive approach to binder jetting has exciting and significant consequences for a variety of manufacturers, including those who make parts with cemented carbide and other tungsten composites. Our latest development collaboration with GTP will help advance the materials necessary to deliver on the vision of producing these parts faster, with less waste and more geometric design freedom.”

GTP 3D Printing Service Using ExOne Technology

GTP will now offer a 3D printing and sintering service for cemented carbide parts. This service can be utilized by customers that wish to explore the feasibility of their new designs. GTP uses an ExOne® Innovent®, an advanced binder jetting system that 3D prints metal, ceramic and composite powders in a compact build area. It offers an advanced form of binder jetting, developed over 20 years, which includes patent-pending methods of dispensing, spreading and compacting powders to deliver exceptional density and repeatability in final products.

Visit ExOne’s website to learn more: https://www.exone.com/.

Visit Global Tungsten & Powders’ website to learn more: https://www.globaltungsten.com

About ExOne

ExOne is a global provider of 3D printing machines, 3D printed products, materials and services to industrial customers. ExOne's business primarily consists of manufacturing and selling 3D printing machines and printing products to specification for its customers using its installed base of 3D printing machines. ExOne’s machines serve direct and indirect applications. Direct printing produces a component; indirect printing makes a tool to produce a component. ExOne offers pre-production collaboration and print products for customers through its network of ExOne Adoption Centers (“EACs”). ExOne also supplies the associated materials, including consumables and replacement parts, and other services, including training and technical support that is necessary for purchasers of its 3D printing machines to print products. The Company believes that its ability to print in a variety of industrial materials, as well as its industry-leading volumetric output (as measured by build box size and printing speed) uniquely position ExOne to serve the needs of industrial customers.

About Global Tungsten

Global Tungsten & Powders is a leading western supplier of tungsten and molybdenum powders, semi-finished parts and SOFC components. At our headquarters in Towanda, PA in the United States, GTP produces ammonium paratungstate (APT), tungsten oxide, tungsten metal powder (WMP), Tungsten Carbide (WC), ready-to-press grade powder (RTP), thermal spray powders (TSP), moly powder, semi-finished parts, and components for the SOFC market segment. GTP also has two manufacturing facilities in Europe – in Brúntal in the Czech Republic GTP produces tungsten metal powders and tungsten carbides, and in Jyväskylä in Finland GTP Tikomet produces recycled tungsten carbide-cobalt powders using the zinc process. With three locations, over 75 years of experience in the tungsten industry and roots dating back to the early 1900’s, GTP has the experience and the global reach required to exceed your expectations.

View source version on businesswire.com: https://www.businesswire.com/news/home/20191029005153/en/

Contact:

ExOne Customers:

Sarah Webster

Global Marketing Director

+1 724 516-2336

Email Contact

ExOne Investors:

Deborah K. Pawlowski / Karen L. Howard

Kei Advisors LLC

+1 716 843-3908 / +1 716 843-3942

Email Contact /

Email Contact

Global Tungsten & Powders Customers:

Laura Morelli

Product Manager Business Unit Refractory & Specialty Powders

+1 570 268-5178

Email Contact