TOKYO — (BUSINESS WIRE) — October 31, 2016 — Toshiba Corporation's (TOKYO: 6502) Storage & Electronic Devices Solutions Company today announced the launch of “TB67S209FTG”, a stepping motor driver with an architecture that lowers noise and vibration during motor operation. Mass production is slated to begin at the end of December.

This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20161031005493/en/

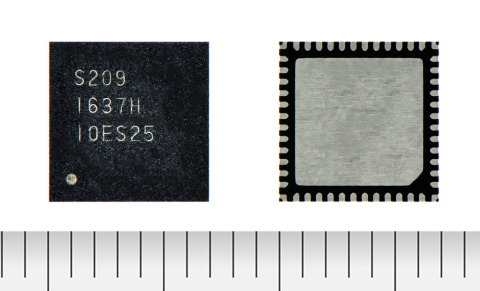

Toshiba:"TB67S209FTG", a stepping motor driver with an architecture that lowers noise and vibration during motor operation. (Photo: Business Wire)

High speed, high performance motor control is essential for printers, office automation equipment, banking terminals such as ATMs, cash dispensers, amusement machines, and home appliances. Recent customer demand for stepping motor control have centered on demands for lower noise and vibration, as equipment is used in increasingly diverse environments.

The key to reducing noise and vibration in a stepping motor is highly efficient operation with accurate current control. Adoption of Selectable Mixed Decay (SMD)[1], a current adjustment function, allows the new IC to reduce noise and vibration by selecting the appropriate SMD setting suitable for the motor.

Use of Toshiba’s state-of-the-art high voltage analog process also improves performance, as it allows the driver to achieve a 50V maximum rating and integrates low on resistance[2] MOSFETs for the motor output to operate at 0.49 Ω (upper + lower: typ.).

Main Features

1. Low noise and vibration

High-resolution 1/32 step (max.) motor

control and the new motor control architecture with SMD lower noise and

vibration.

2. Less heat generation

Heat generation is reduced by low on

resistance (0.49 Ω (upper + lower: typ.)).

3. Small package

Packaging in a small QFN package will allow

customers to reduce heat problems and simplify PCB design patterns for

heat dissipation. It will also realize an affordable solution in terms

of space and cost.

4. Built-in error detection circuits

Thermal shutdown, over-current

shutdown and under voltage lock out circuits contribute to equipment

safety and reliability.

|

Main Specifications of New Product |

|||

| Product name | TB67S209FTG | ||

| Control I/F | CLK-IN | ||

| Absolute maximum ratings | 50V, 4A | ||

| Package | QFN48 | ||

| Step resolution | Full, Half, Quarter, 1/8, 1/16, and 1/32 step resolution | ||

| Other features |

- SMD; a current control method for efficient motor operation

- Built-in error detection functions (thermal shutdown, over-current shutdown, and under voltage lock out) - Built-in error detection signal output function - Supports the power-on sequence by the single power drive |

||

| Mass production | End of December, 2016 (scheduled) | ||