2021 1.0 Enables Automatic Measurement Planning, Process Automation, and Expands Support for Mesh-Based Data

BROOMFIELD, Colo. — (BUSINESS WIRE) — November 10, 2020 — Spatial Corp, the leading provider of 3D software development toolkits for design, manufacturing, and engineering solutions, and a subsidiary of Dassault Systèmes, announces today the production release of 2021 1.0. This release delivers new advances in automatic measurement planning utilizing 3D InterOp, improved robustness for manufacturing workflows for both CGM Modeler and 3D ACIS Modeler, as well as enhanced support for mesh-based data.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20201110006192/en/

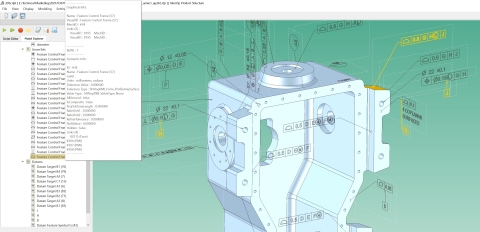

NIST STEP AP242 model imported using 3D InterOp (Photo: Business Wire)

3D InterOp expands upon PMI Support to Enable Automatic Measurement Planning and Enhanced MBD Review

Easy-to-Use, market-leading metrology software enables measurement planning rather than cumbersome and archaic measurement programming. Using Spatial’s 3D Interop, developers are able to build metrology software that automatically generates measurement plans and preserves design intent by importing PMI (Product Manufacturing Information) from 3D CAD models directly into applications.

3D InterOp imports both semantic PMI (machine-readable) and graphical PMI (human-readable), along with Views, Captures, and links to 3D geometry. With this release, 3D InterOp supports this functionality for STEP AP 242 and JT. This is in addition to existing support for PMI in CATIA, NX, Creo, and SOLIDWORKS CAD formats. Because of 3D InterOp’s native support of regular CAD version updates, developers can focus on CMM/Metrology solutions.

Also new in 2021 1.0: enable customers to achieve MBE Maturity Index Level 4 by allowing them to export STEP AP 242 models annotated with lightweight, viewable PMI. Using 3D InterOp, engineering applications can export graphical PMI linked to 3D geometry with pre-defined views to STEP AP 242 files. This allows collaboration between designers and manufacturing engineers or suppliers; teams can simultaneously develop the product’s design as well as manufacturing methods.

A designer using an application built with 3D InterOp can export a CAD model with PMI to STEP AP 242, delivering explicit dimensions, tolerances, and manufacturing annotations to their peers while protecting their IP. This STEP model can then be used in a following design-for-manufacturing review with members of teams such as process engineering, quality control or fabrication, to provide early feedback on production concerns or anticipate production requirements about the designed part.

Further Enablement for Fast Reviews of Large Models

3D InterOp’s selective import ability lets developers optimize data preparation application for handling large CAD models. In April of this year, Spatial made considerable improvements to CATIA and SOLIDWORKS import. For 2021 1.0, further improvements have been added for JT visualization import from large models, increasing performance by as much as double.

Build Process Automation and Powerful CAD Simplification Workflows with CGM Modeler’s Feature Recognition and Defeaturing

With 2021 1.0, CGM’s native feature recognition adds new support for chamfer recognition in addition to robustness improvements for filleted pads, pockets and slots. Most 3D CAD models designed for machining have chamfers and fillets, and with these new additions developers can use identified features to analyze models for manufacturing time and cost, simplify parts by removing chamfers or fillets when they are not necessary for part function, and fix manufacturability concerns without access to the feature tree. This release also supports sheet metal cut-out recognition.

Most feature recognition in CAD and CAM applications fail when features such as holes are more complex than standard configurations such as Bore Holes, Counter Bore Holes and Counter Sunk Holes. With 2021 1.0, CGM’s feature recognition can identify and remove complex, interacting, or otherwise non-standard holes using geometric properties. Additionally CGM Modeler’s defeaturing can handle interactive workflows to remove combined features.

Expand Your Support for Mesh-Based Data Regardless of Quality with CGM Polyhedra

Mesh based data often comes with quality issues, precluding further analysis or manufacturability. Complex 3D surfaces with a lot of local variations make smoothly filling gaps difficult. 2021 1.0 provides a robust and advanced algorithm to fill non-planar holes leveraging local topology. CGM Polyhedra offers flat patching of holes, refinement and smoothing, to produce high quality results that conform to local curvature.

ACIS Modeler is Serving the World’s Leaders in 3D Modeling with Solutions to Industrial Challenges

At each release, the ACIS team improves upon its quality as a proven modeler and acts as solution advisor to leaders in the CAD/CAM/CAE industry, all while expanding support for ACIS customers to benefit from Spatial’s ecosystem of technology. 2021 1.0 brings improvement of workflows requiring precision, such as workflows providing data preparation for manufacturing of imported data.

Significant performance improvements in the ACIS checker, as well as healing of gaps at tight tolerances, leads to faster import of CAD models into ACIS. The bounding box computation with exact mode is now faster by caching and eliminating unnecessary calculations through recognition of faces and edges that contribute to the exact box. This improves performance for all workflows relying on the most precise bounding boxes. Improvements are most significant on very large models with non-analytic geometry.

With 2021 1.0, Spatial has added new support to slice exact B-Rep models at multiple locations using a single ACIS call. Slicing is also now multi-threaded, leading to a cumulative speed of up to two times what was available previously. This enables the use for more precise exact models in manufacturing workflows.

Other Release Highlights

This release also delivers a number of other improvements for various Spatial components. For more information, see the full list of highlights on Spatial.com.

About Spatial Crop

Spatial Corp, a Dassault Systèmes subsidiary, is the leading provider of 3D software development toolkits for technical applications across a broad range of industries. Spatial 3D modeling, 3D visualization, and CAD translation software development toolkits help application developers deliver market-leading products, maintain focus on core competencies, and reduce time-to-market. For over 30 years, Spatial’s 3D software development toolkits have been adopted by many of the world's most recognized software developers, manufacturers, research institutes, and universities. Headquartered in Broomfield, Colorado, Spatial has offices in the USA, Germany, Japan, China, and the United Kingdom. For more information, visit www.spatial.com.

View source version on businesswire.com: https://www.businesswire.com/news/home/20201110006192/en/

Contact:

Spatial Corp. Press Contact

Stevie Caldarola

+1 508 305 5180

Email Contact